2-Year Warranty on All Panels

2-Year Warranty on All Panels

In 2025, acoustic wall panels remain a key design ingredient for modern interiors. With increasing awareness of sound wellness and environmental impact, consumers now demand materials that deliver both aesthetic appeal and acoustic performance. In this guide, we compare the most effective and fashionable acoustic materials available—helping designers, homeowners, and acoustic professionals choose wisely.

What they are:

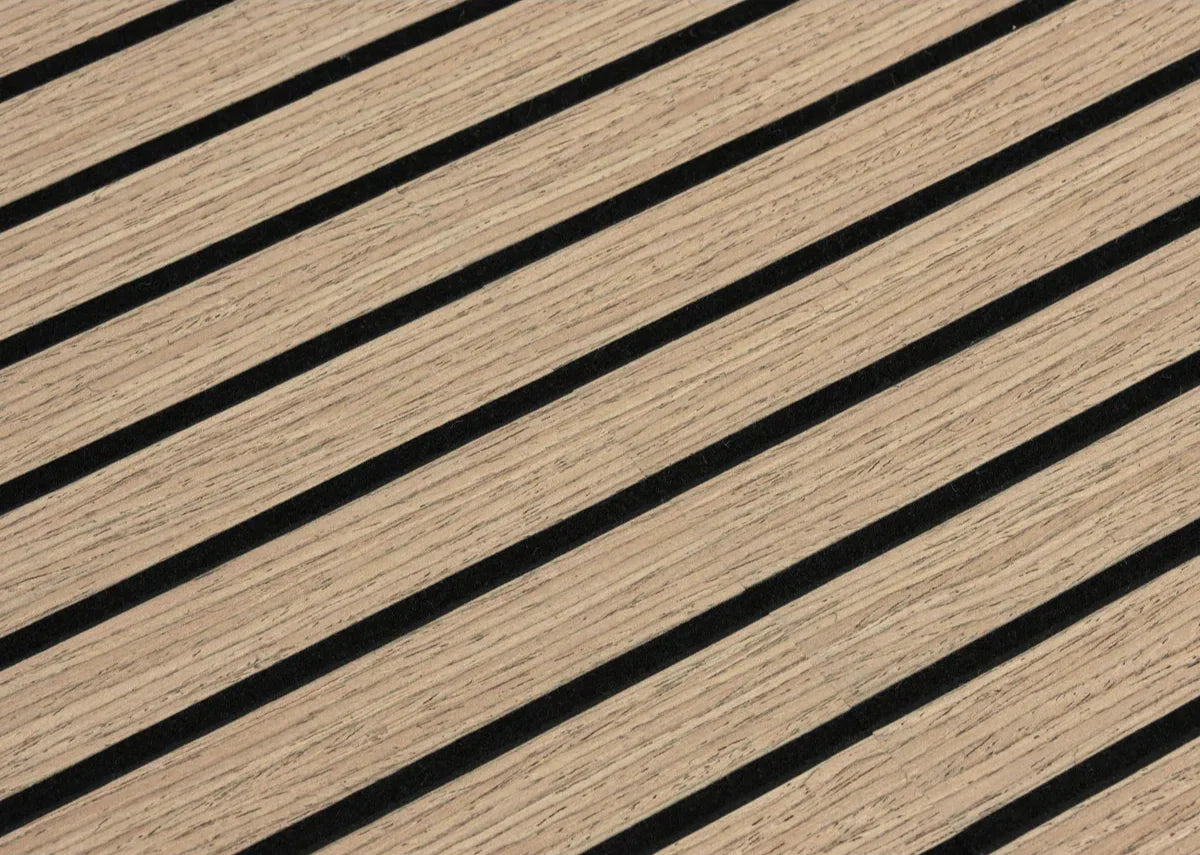

Real wood veneer (oak, walnut, smoked oak, black oak) bonded to eco‑friendly MDF, backed with recycled PET or polyester felt.

Why they’re trending:

Blend high-end decor with effective mid-to-high frequency absorption

Visually stunning textures and geometric formats like slats or hexagons

Easy DIY-friendly installation; high user preference for natural wood OVER synthetics

Performance & applications:

Typical NRC = 0.6–0.9 depending on thickness and felt density. Ideal for residential living rooms, home studios, and offices. Available in a variety of colors and finishes.

What they are:

Panels made from recycled polyester felt, sometimes CNC-cut into shapes/diffusers.

Why they matter:

Up to 90% recycled material content, zero-VOC and non-toxic

Highly customizable shapes and colors; trendy in hospitality and co-working

Acoustic strength:

Effective in mid-to-high frequencies, NRC typically 0.5–0.7. Combined with slat fronts or backing, they offer high performance plus design flexibility.

What they are:

Panels with cores of Owens Corning 703, rock wool, or fiberglass wrapped in acoustically transparent fabric.

Advantages:

Superior broad-range sound absorption, including low frequencies

Fire-resistant, mold-resistant, used in cinemas, studios, classrooms

Best for:

Your professional setups—studios, conference rooms, high-end podcast studios.

What they are:

Wall panels made from natural cork or agglomerated cork sheets.

Benefits:

Renewable and sustainable; excellent thermal + acoustic insulation

Soft texture, unique visuals for eco-themed interiors

Naturally fire-resistant, hypoallergenic

Limitations:

Lower sound absorption at very low frequencies; needs careful maintenance.

Mycelium (fungi-based panels):

Panels grown from biomass like oyster mushroom mycelium. Offer mid-to-high frequency absorption close to foam, but still in experimental stages with limited commercial availability

Algae, seaweed, oyster shell composites:

Used in eco‑bricks or blend panels with acoustic and decorative function. Capture CO₂ and act as carbon storage—though cost and standardization still barriers to scale

These materials are ideal for eco-conscious projects and future-forward design narratives.

Sandwich panels:

Composed of foam or mineral wool with rigid facing layers. Offer thermal + acoustic insulation (≈25–30 dB STC at proper specs) and lightweight options for commercial walls

Labyrinthine/metamaterial designs:

3D-printed or structured designs optimizing broadband absorption across low-to-mid frequencies while minimizing thickness—innovative, but still niche

NRC (Noise Reduction Coefficient): Measures absorption effectiveness over mid/high frequencies.

STC (Sound Transmission Class): Measures sound blocking/transmission across partitions (building-level). Wood veneer + felt panels typically shift NRC more than STC.

For studio or conference room use, aim for panels rated NRC ≥ 0.6 and combine with bass traps or insulation for lower frequencies.

| Material Type | NRC Range | Aesthetic Appeal | Sustainability | Best Use Case |

|---|---|---|---|---|

| Wood veneer + PET felt | 0.6–0.9 | High (natural finishes) | Medium–High | Living rooms, home offices, decorative walls |

| Recycled PET felt panels | 0.5–0.7 | High (colored/shapes) | High | Modern offices, hospitality, co-working |

| Mineral wool / fiberglass fabric-wrapped | 0.7–1.1 | Medium (soft look) | Medium (depends core) | Studios, theaters, professional spaces |

| Cork | 0.4–0.6 | Natural, earthy | Very high | Eco-themed or thermal + acoustic needs |

| Bio-based (mycelium/algae) | 0.4–0.8* | Experimental, organic | Very high | Sustainable design concepts |

| Sandwich / metamaterial panels | Varies | Tech-driven, modular | Medium–Low | Commercial, sound‑critical installations |

Market Trends: Commercial and residential users now prioritize design + acoustic function. The demand for sustainable, multi-functional panels continues to grow globally, especially in North America and Europe

Wellness & Sustainability: Acoustic comfort ties into holistic wellness—less noise, healthier materials, sustainable sourcing

Customization & Smart Features: Consumers increasingly seek personalized panels (custom shapes, colors, modularity), with future-ready products like smart panels that adapt absorption properties dynamically

Unisoar’s wood veneer acoustic panels offer an ideal fusion of these trends:

Real American oak/walnut finishes with eco PET felt backing

3D slatted patterns, hexagon or square modules

NRC ≈ 0.7+ in real installations

Sustainable MDF plus recyclable felt materials

Stylish enough for design-forward interiors, while meeting acoustic needs

They strike the balance between performance, visual elegance, and green credentials.

Define your acoustic goal: Reduce echo (mid/high), isolate noise (bass), or both.

Check NRC for absorption, STC for transmission.

Balance look & function: veneer for decor, felt/fabric for acoustic depth.

Prioritize sustainable materials when possible.

Consider modularity & shape for custom spaces or design focal points.

Whether you're improving speech clarity in a home office or elevating ambiance in a boutique café, selecting the right acoustic wall material makes a difference. In 2025, wood veneer + eco-felt panels remain the top choice for interiors that demand style and sound control. For higher bass absorption, integrate with mineral wool modules or add bespoke sandwich-style acoustic boards. And for eco-minded designs, explore cork or pioneering bio-material alternatives.

Unisoar’s acoustic wall panel range embodies the modern blend of performance and aesthetics. If you'd like case studies, real-world installation photos, or acoustic test results (NRC/STC) for specific Unisoar productsy.